Robotic arms are transforming industries like manufacturing and healthcare, making them more efficient and innovative. Because robotics is developing so quickly, these machines are always changing. However, with many types of robotic arms to choose from, how do you pick the best one for your needs?

- What is a Robotic Arm?

- Robot Arm Types in 2025

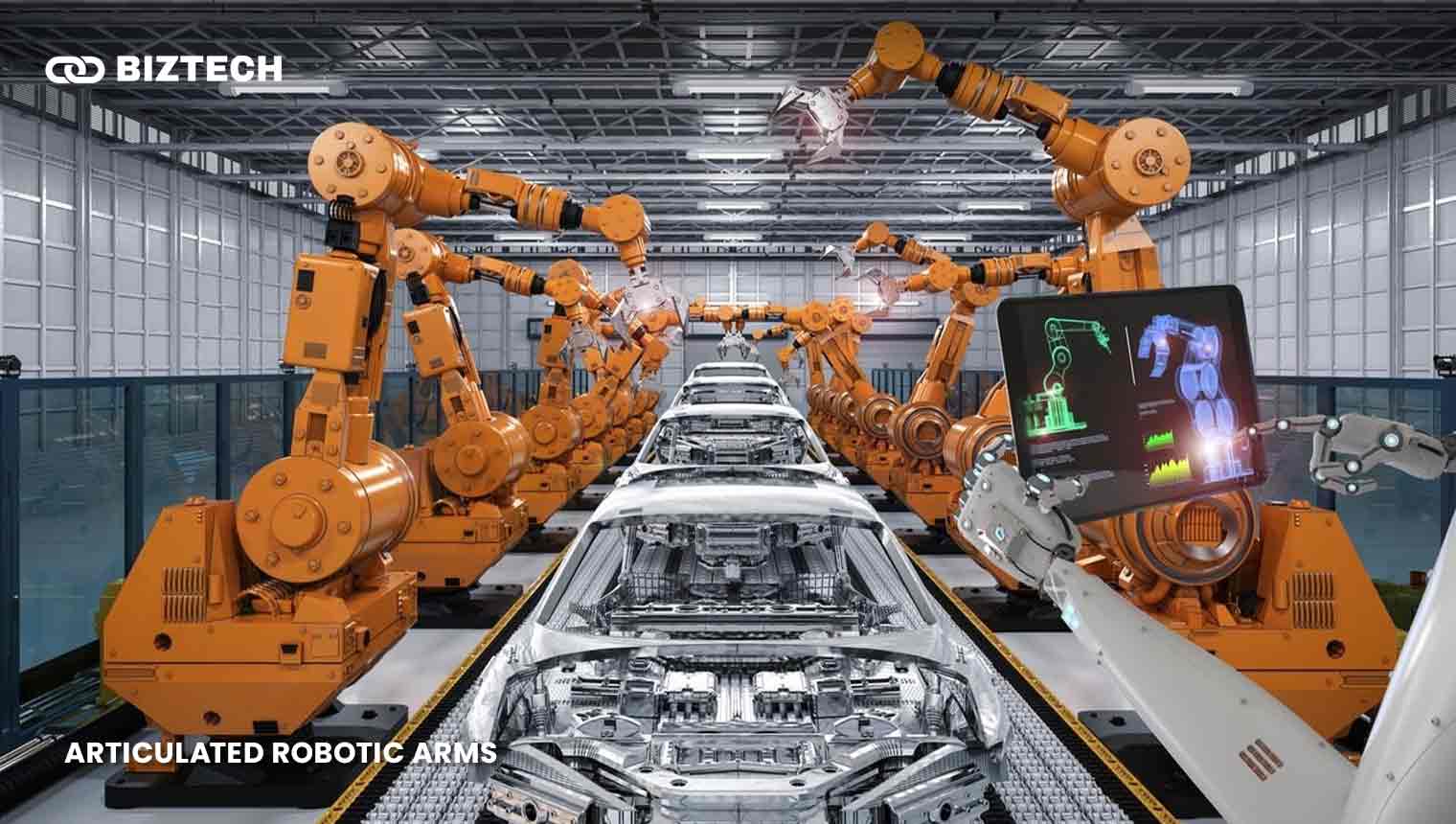

- 1. Articulated Robotic Arms

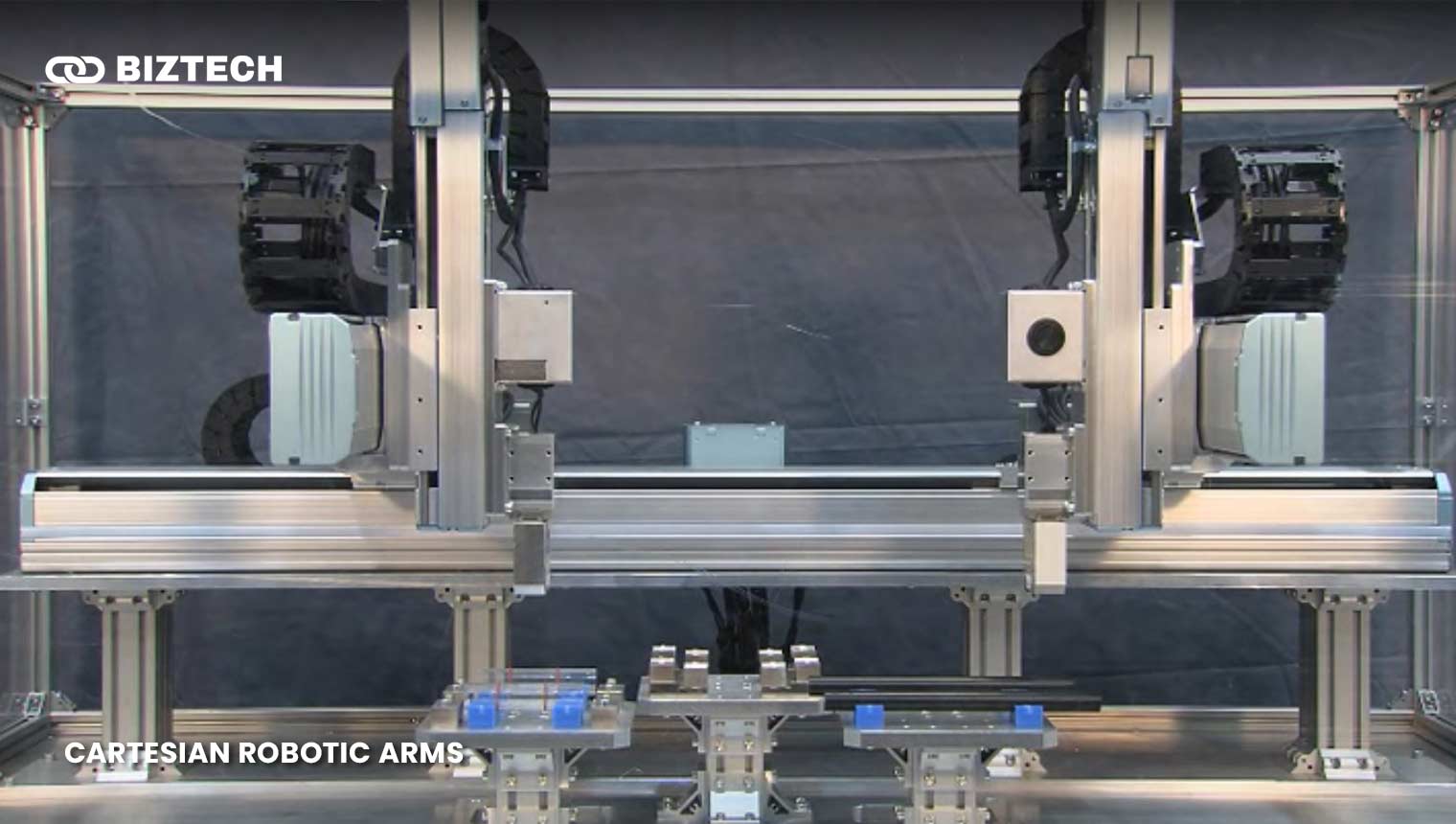

- 2. Cartesian Robotic Arms

- 3. SCARA Robots (Selective Compliance Assembly Robot Arm)

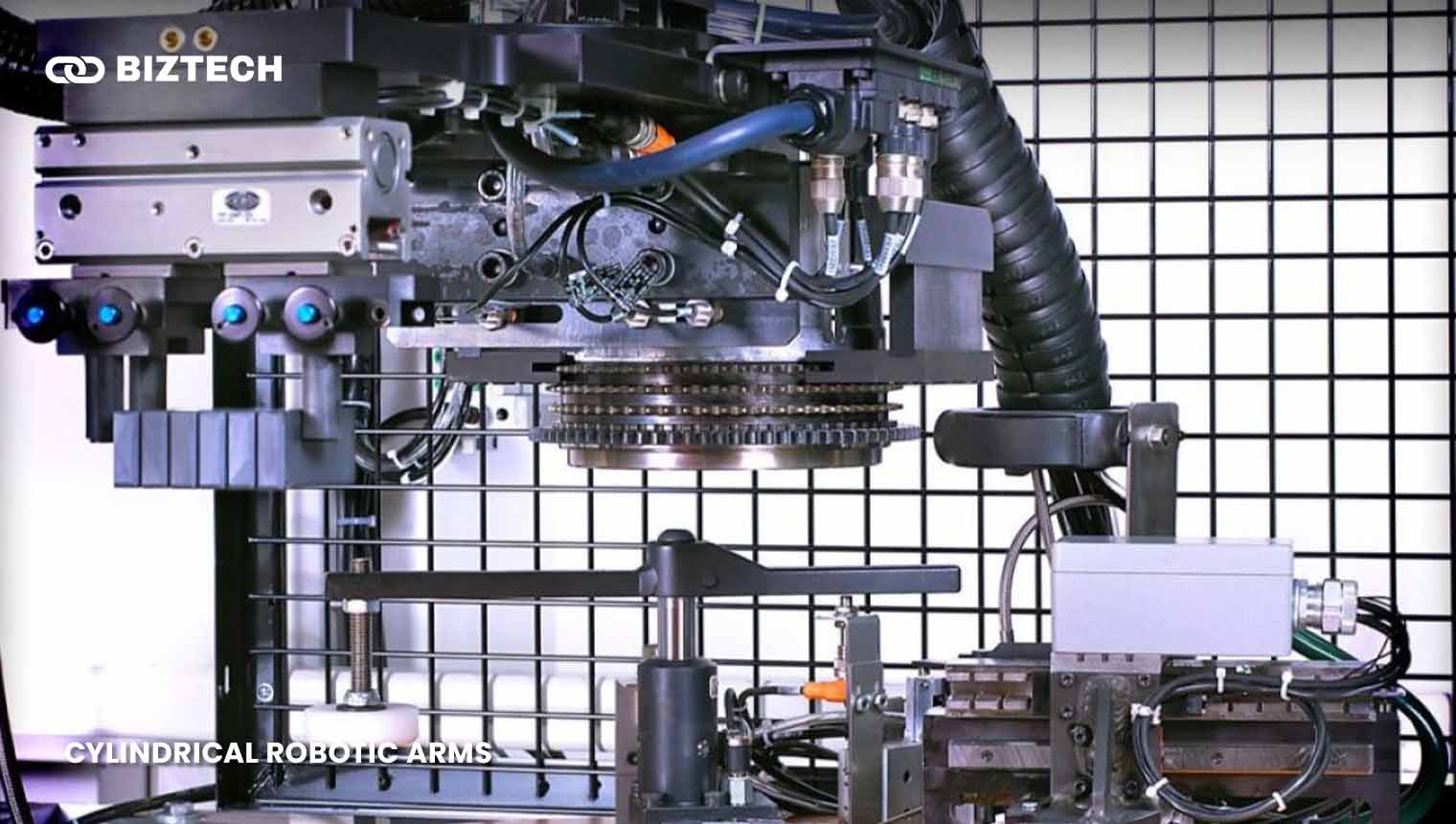

- 4. Cylindrical Robotic Arms

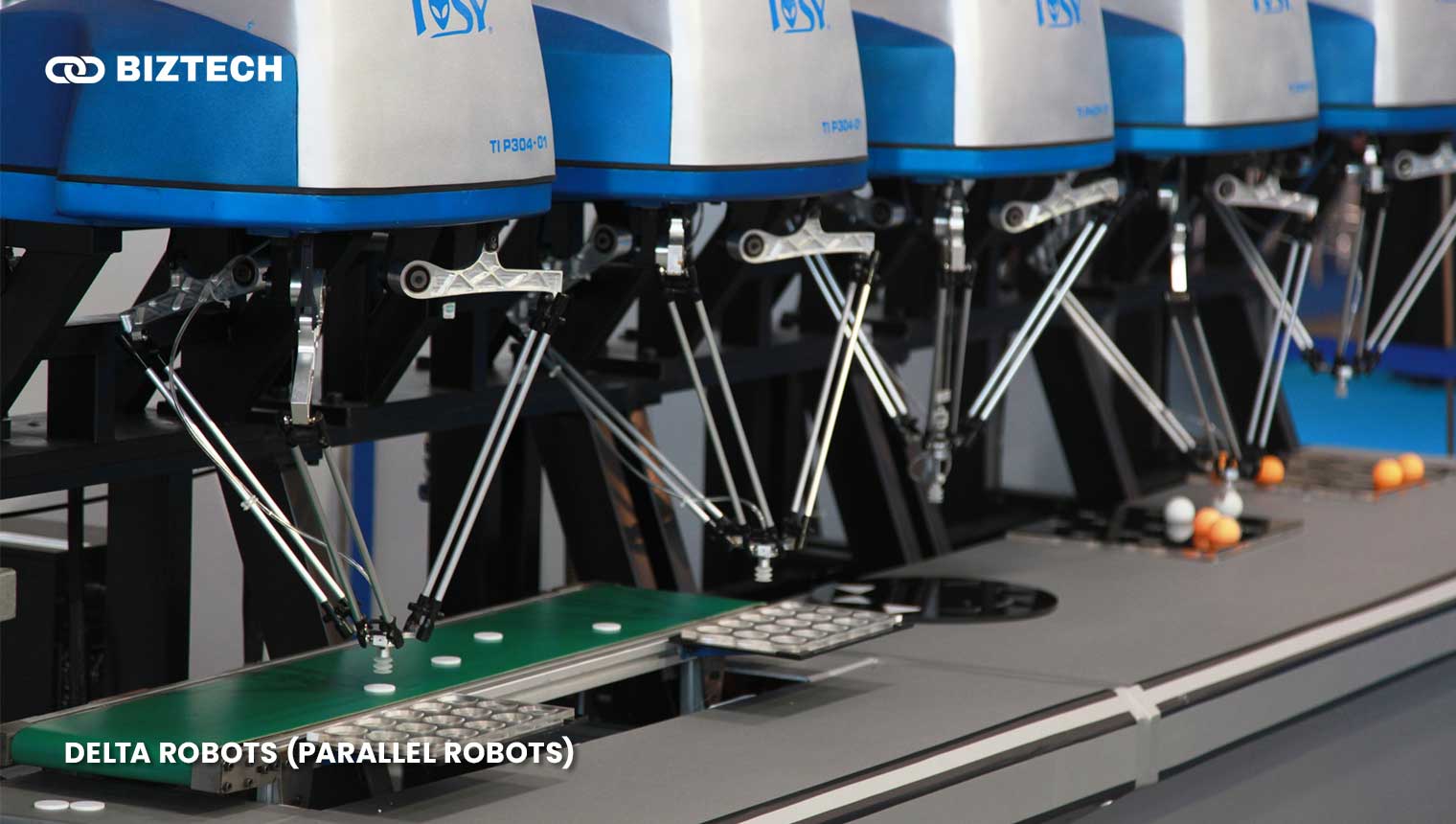

- 5. Delta Robots (Parallel Robots)

- 6. Collaborative Robotic Arms (Cobots)

- Factors to Consider When Choosing a Robot Arm

- Task Requirements (Precision, Speed, Load Capacity)

- Industry-Specific Needs

- Budget and ROI

- Ease of Integration and Programming

- Emerging Trends in Robotic Arms for 2025

- AI and Machine Learning Integration

- Increased Use of Soft Robotic Arms

- IoT-Enabled Robotic Arms

- Sustainability in Robotic Arm Design

- Applications of Robotic Arms Across Industries

- Agriculture and Food Processing

- Space Exploration and Defense

- Education and Research

- Conclusion

- Frequently Asked Questions (FAQs)

Knowing these robots is essential to staying ahead, whether you are an engineer, business owner, student, or simply a tech enthusiast. In this blog post, we’ll break down the different types of robotic arms and share expert insights on how they’ll shape the future by 2025. Let’s get started!

What is a Robotic Arm?

A robotic arm is a special kind of robot that can grab and move things, just like a human arm but with greater precision and strength. These arms are key to automation, making repetitiv e or complex tasks faster and more accurate.

Over the years, robotic arms have evolved from simple machines to advanced tools powered by AI and sensors. You’ll find robotic arms playing a key role in everything from building cars to performing surgery and exploring other planets. Understanding the different types of robotic arms helps us see how they can solve real-world problems and shape the future.

Robot Arm Types in 2025

You’ll find robotic arms everywhere these days – in factories, hospitals, and more. Let’s explore the different robotic arm types and see how they’ll be used in the future!

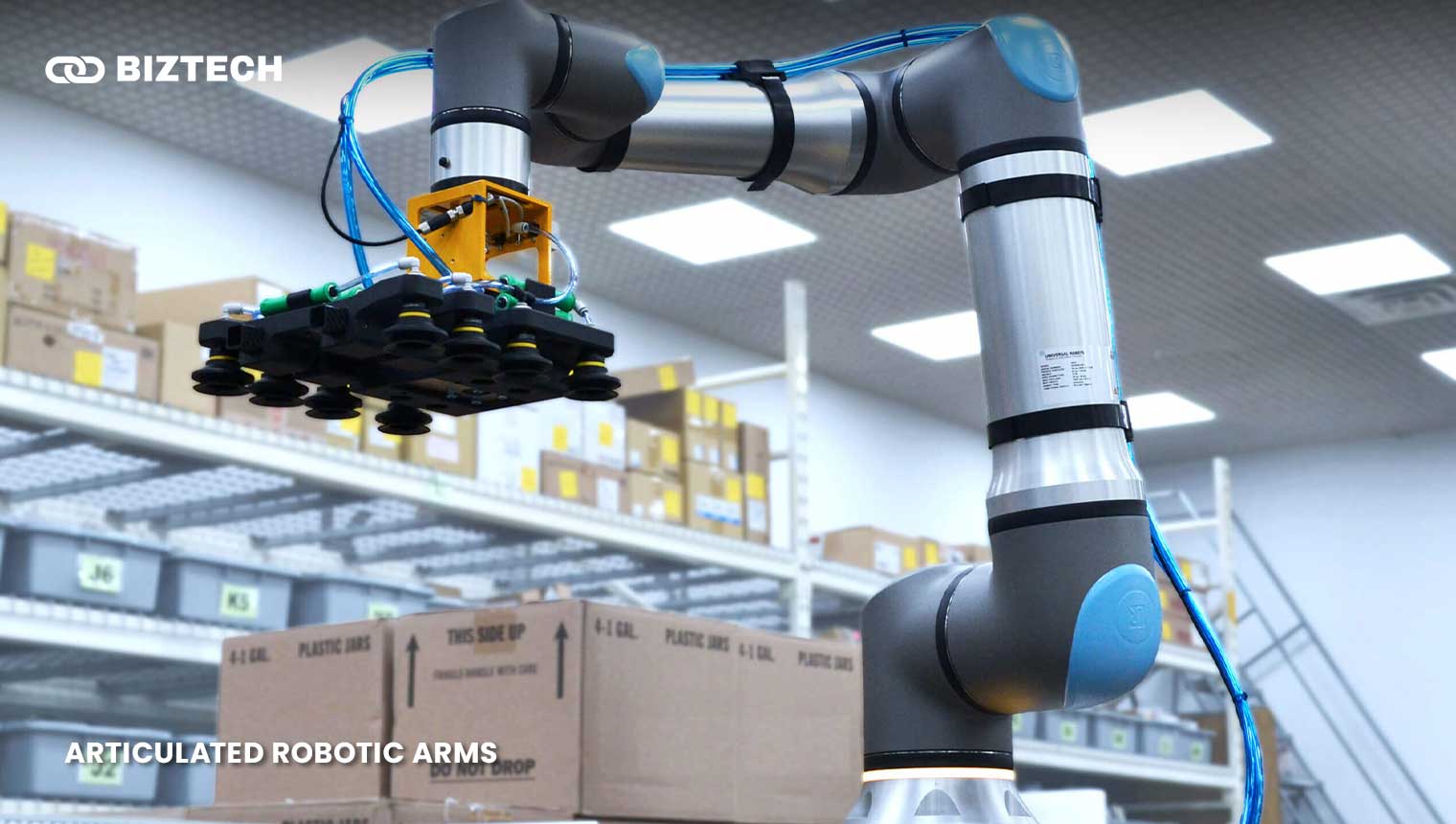

1. Articulated Robotic Arms

These arms have lots of flexible joints, just like our arms. They’re great for tasks like welding, assembly, and moving materials because they’re very flexible.

- Advantages: High range of motion and versatility.

- Examples: Industrial robots like the FANUC M-2000iA.

2. Cartesian Robotic Arms

These arms move linearly, following three axes: X, Y, and Z, like a grid. They’re perfect for 3D printing, CNC machines, and pick-and-place jobs.

- Advantages: Simple design and high precision.

- Examples: Gantry robots used in factories.

3. SCARA Robots (Selective Compliance Assembly Robot Arm)

What makes SCARA robots special is their two parallel joints. They’re ideal for assembly, packaging, and stacking tasks.

- Advantages: Speed and precision in horizontal work.

- Examples: EPSON Robots.

4. Cylindrical Robotic Arms

These arms rotate at the base and move up and down. They’re used for machine loading, coating, and assembly in tight spaces.

- Advantages: Compact design and strong lifting power.

- Examples: Older models like the IBM 7565.

5. Delta Robots (Parallel Robots)

Delta robots are lightweight and fast, with arms connected to a shared base. They excel in high-speed tasks like food packaging and pharmaceuticals.

- Advantages: Incredible speed and precision.

- Examples: ABB FlexPicker.

6. Collaborative Robotic Arms (Cobots)

Cobots are designed to work safely with humans. They’re used in small factories, healthcare, and even schools because they’re easy to program and affordable.

- Advantages: Safe, user-friendly, and cost-effective.

- Examples: Universal Robots UR series.

By 2025, these robotic arms will become even more advanced, making them essential tools across industries.

Factors to Consider When Choosing a Robot Arm

Selecting the right robotic arm depends on what you want to accomplish and the challenges you face. When selecting a robotic arm, the following are the most important things to consider.

Task Requirements (Precision, Speed, Load Capacity)

First, think about what the robotic arm needs to do. If your task requires high precision, like assembling tiny electronics, an articulated or SCARA robot might be ideal.

For heavy lifting, a cylindrical or articulated arm with high load capacity works best. Speed is another factor—delta robots excel in fast, repetitive tasks like packaging.

Industry-Specific Needs

Different industries have unique demands. In healthcare, collaborative robots (cobots) are great for safe human interaction. For manufacturing, articulated or Cartesian arms are often the go-to for assembly lines. Always consider what your industry requires.

Budget and ROI

Robotic arms come in a wide price range. While advanced models with AI features may cost more, they can save money in the long run by boosting efficiency. Think about your budget and how quickly the robot can pay for itself.

Ease of Integration and Programming

Lastly, make sure it’s easy to set up and program the robotic arm. Collaborative robots are user-friendly and don’t need expert programmers. If you need to do complex tasks, make sure the robot can easily work with your other equipment.

By weighing these factors, you can find the right robotic arm to meet your needs and stay ahead in 2025.

Emerging Trends in Robotic Arms for 2025

The world of robotic arms is evolving fast, with new technologies shaping their future. Let’s talk about the biggest trends shaping the future of robotic arms.

AI and Machine Learning Integration

Thanks to AI, robots are getting smarter and more efficient. They can now predict when they need maintenance, reducing downtime. Adaptive learning helps them get better at what they do, even when things get tricky.

Increased Use of Soft Robotic Arms

Soft robotic arms are flexible and gentle, perfect for delicate tasks. They’re being used in medical surgeries to handle sensitive tissues. They’re also great for picking up fragile items like fruits or glassware without damage.

IoT-Enabled Robotic Arms

IoT connects robotic arms to the internet, making them part of a larger smart system. In smart factories, they share real-time data to optimize production. This makes automation more efficient and helps reduce errors.

Sustainability in Robotic Arm Design

Robotic arms are becoming more eco-friendly. Manufacturers are using lightweight materials to save energy. Using renewable energy to power robots is good for the environment and it can also help you save money on energy costs.

These trends show how robotic arms are becoming smarter, softer, and more sustainable.

Applications of Robotic Arms Across Industries

Robotic arms are making waves in countless fields, solving problems and boosting efficiency. Let’s dive into how they’re being used in agriculture, space exploration, and education.

Agriculture and Food Processing

In farming, robotic arms are revolutionizing tasks like harvesting crops and sorting produce. They also play a big role in packaging food, ensuring it’s done quickly and hygienically.

Space Exploration and Defense

Robotic arms are essential in space missions, helping with tasks like repairing satellites and collecting samples. In defense, they’re used for bomb disposal and handling dangerous materials safely.

Education and Research

Students are learning about robotics and automation by working with real robotic arms in schools and labs. They’re also vital in research, helping scientists test new ideas and conduct experiments with precision.

Conclusion

Understanding the different types of robotic arm is important for anyone working in engineering, manufacturing, healthcare, or research. Each type has unique strengths, making it essential to choose the right one for your needs.

As we move toward 2025, advancements in robotics will continue to transform industries. From AI integration to sustainable designs, these innovations will make robotic arms smarter, faster, and more eco-friendly.

Stay on top of the latest trends in robotic arms to make sure you’re always up-to-date. Now is the perfect moment to investigate how these tools can help your work, regardless of whether you are a professional, student, or business owner. Let’s get started today!