Robotic arm technology has come a long way, transforming how we work in the manufacturing, healthcare, and research industries.

- What is a Robotic Arm?

- How Does a Robotic Arm Work?

- The Basic Structure

- Power and Control

- Programming and Automation

- Advanced Features

- How Much is a Robotic Arm?

- Robotic Arm Parts

- Joints and Links

- Actuators

- End-Effector

- Sensors

- Controller

- The Current State of Robotic Arm Technology

- Applications of Robotic Arms in 2025

- Challenges Facing Robotic Arm Adoption

- Key Innovations in Robotic Arm Technology for 2025

- AI and Machine Learning Integration

- Advanced Materials and Lightweight Designs

- Human-Robot Collaboration (Cobots)

- Enhanced Precision and Sensory Capabilities

- 5G and IoT Connectivity

- The Future Impact of Robotic Arm Technology

- Economic and Workforce Implications

- Sustainability and Environmental Benefits

- Ethical Considerations and Safety Standards

- Conclusion

- Frequently Asked Questions (FAQs)

But as demands grow, so do precision, speed, and adaptability challenges. What if these robotic arms could do even more by 2025?

This article explores the exciting new advancements shaping robotic arm technology’s future. Discover how these advancements will revolutionize industries and solve today’s biggest problems, from smarter AI to better materials and new applications.

Want to know what the future of robotic arms holds? Let’s start!

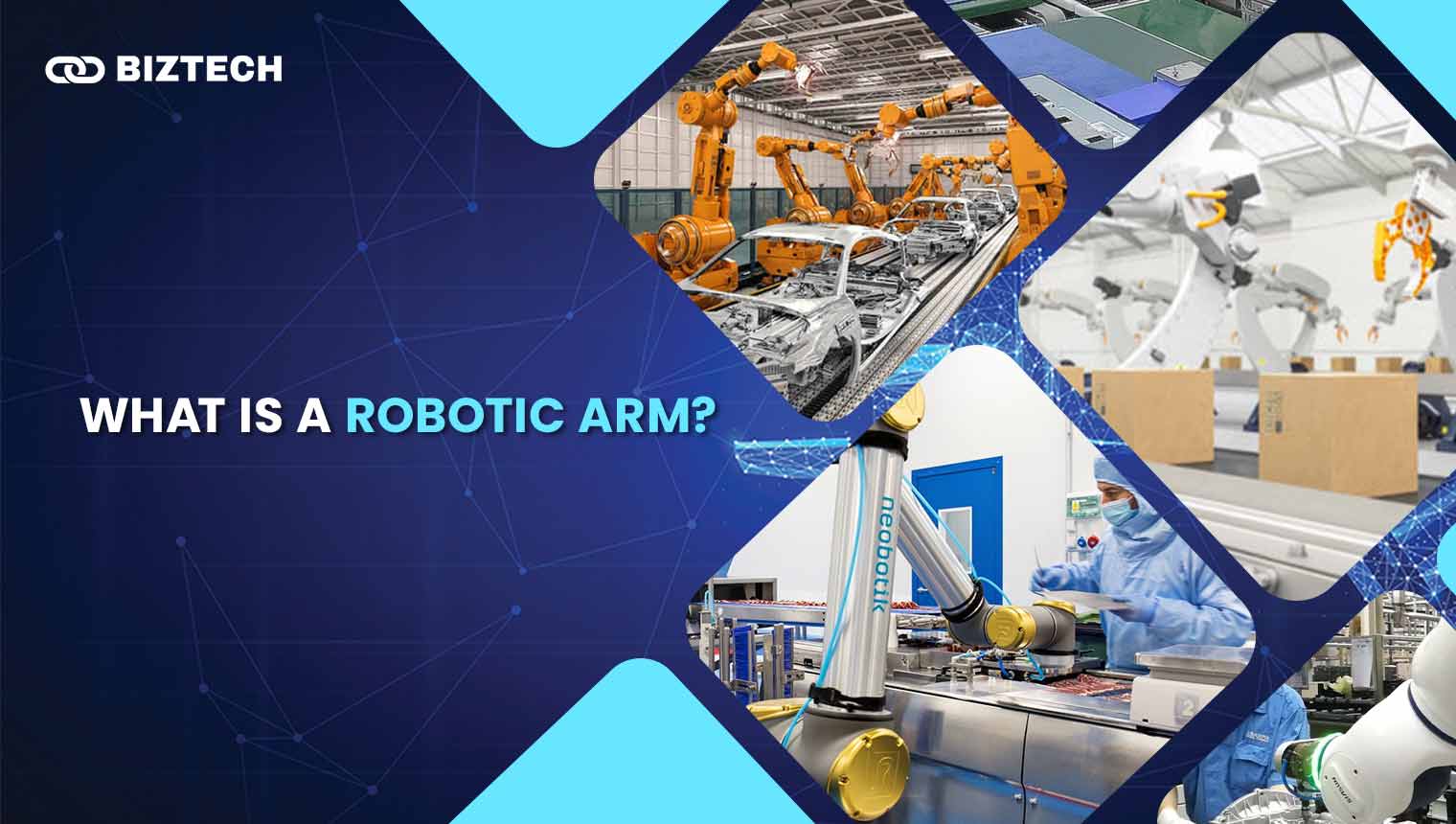

What is a Robotic Arm?

A robotic arm performs tasks like lifting, moving, and assembling objects. It works like a human arm but with greater precision and strength.

These arms are powered by motors and controlled by computers or remote operators. They can be programmed to repeat tasks accurately, making them ideal for factories, hospitals, and space exploration.

Robotic arms are versatile tools that can be used for everything from building cars to assisting in surgeries. They help people work faster, safer, and more efficiently in many industries.

How Does a Robotic Arm Work?

Robotic arms are fascinating machines that mimic human arm movements but with more precision and strength. Let’s figure out how robotic arms work and why they’re so good at what they do!

The Basic Structure

A robotic arm typically has joints, a wrist, and an end effector, the “hand” performing tasks. These parts work together to move and manipulate objects.

Power and Control

Motors and sensors power the arm, while a computer or controller tells it what to do. The sensors help the arm “feel” and adjust its movements for accuracy.

Programming and Automation

Robotic arms follow programmed instructions to perform tasks like welding, painting, or lifting. They can repeat these tasks perfectly, making them ideal for factories and labs.

Advanced Features

Some robotic arms use AI to learn and improve over time. Others have cameras or sensors to “see” and adapt to their surroundings, making them even smarter.

How Much is a Robotic Arm?

The price of a robotic arm depends on what it can do. Simple robotic arms for basic tasks can start at a few thousand dollars.

More advanced robotic arms, like those used in factories or hospitals, can cost tens of thousands of dollars. High-end models with AI or precision capabilities may even reach hundreds of thousands.

Robotic Arm Parts

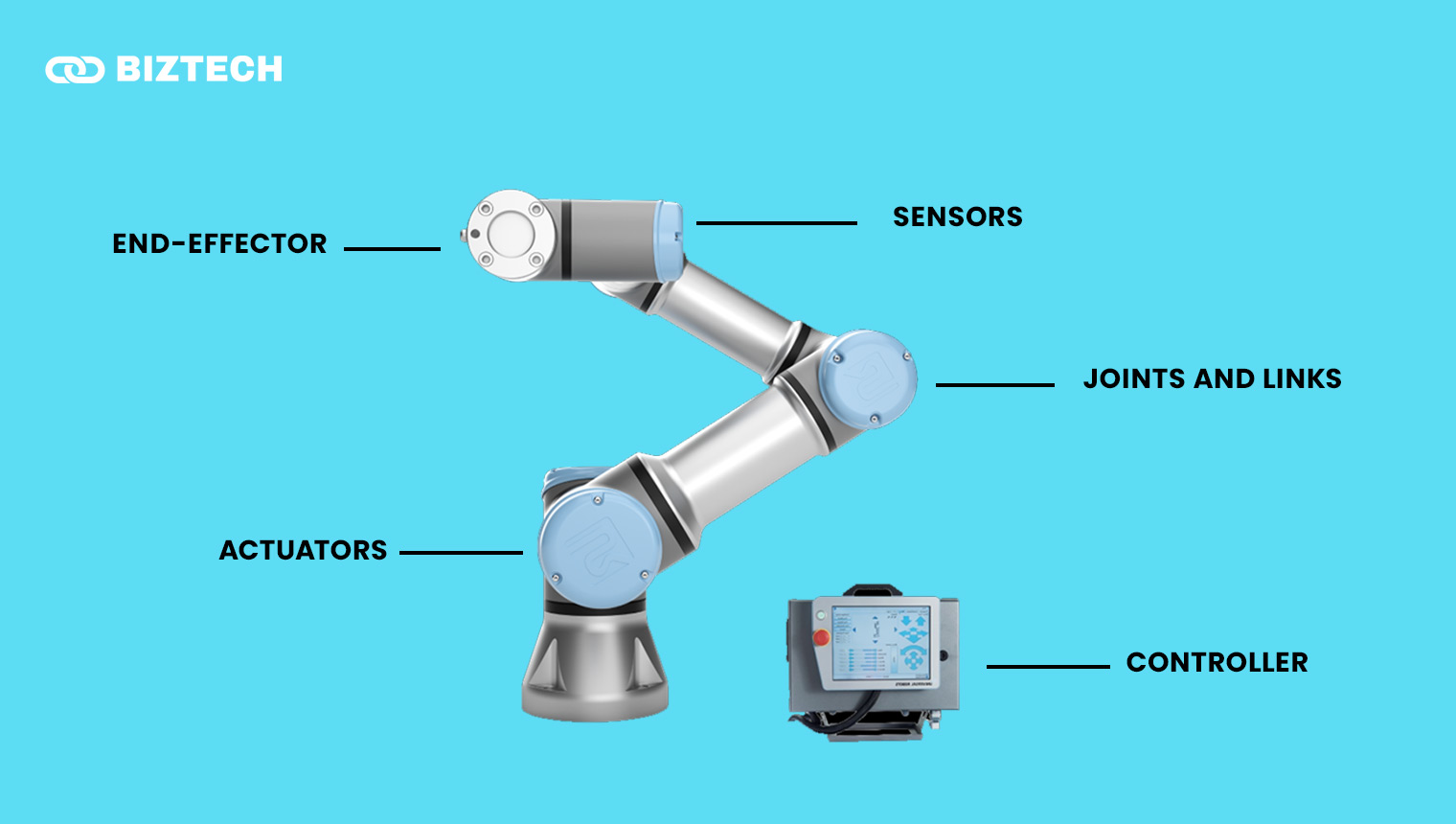

You could say a robotic arm is like a puzzle, where each part – from the joints to the motors – plays a crucial role in its overall functionality. Each part has a specific role, making the arm flexible, strong, and precise.

Joints and Links

Joints act like the elbow or shoulder of a human arm, allowing movement. Links are the rigid parts connecting the joints, giving the arm its structure.

Actuators

Actuators are the key components that allow a robotic arm to move. They use motors or hydraulics to power the arm’s movements, making it lift, twist, or bend.

End-Effector

Think of the end-effector as the ‘hand’ of the robotic arm. It can be a gripper, welder, or even a camera, depending on the task it needs to perform.

Sensors

Sensors help the arm “see” and “feel” its surroundings. They provide feedback to ensure the arm moves accurately and avoids collisions.

Controller

The controller is the central command center for the robotic arm. It processes instructions and tells the arm how to move, ensuring tasks are done correctly.

The Current State of Robotic Arm Technology

Robotic arm technology has made huge strides in recent years, becoming a key tool in many industries. Let’s explore where it stands today and what challenges still exist.

Applications of Robotic Arms in 2025

Robotic arms assemble products, weld parts, and paint surfaces with unmatched precision in manufacturing. They work faster than humans and reduce errors, boosting productivity.

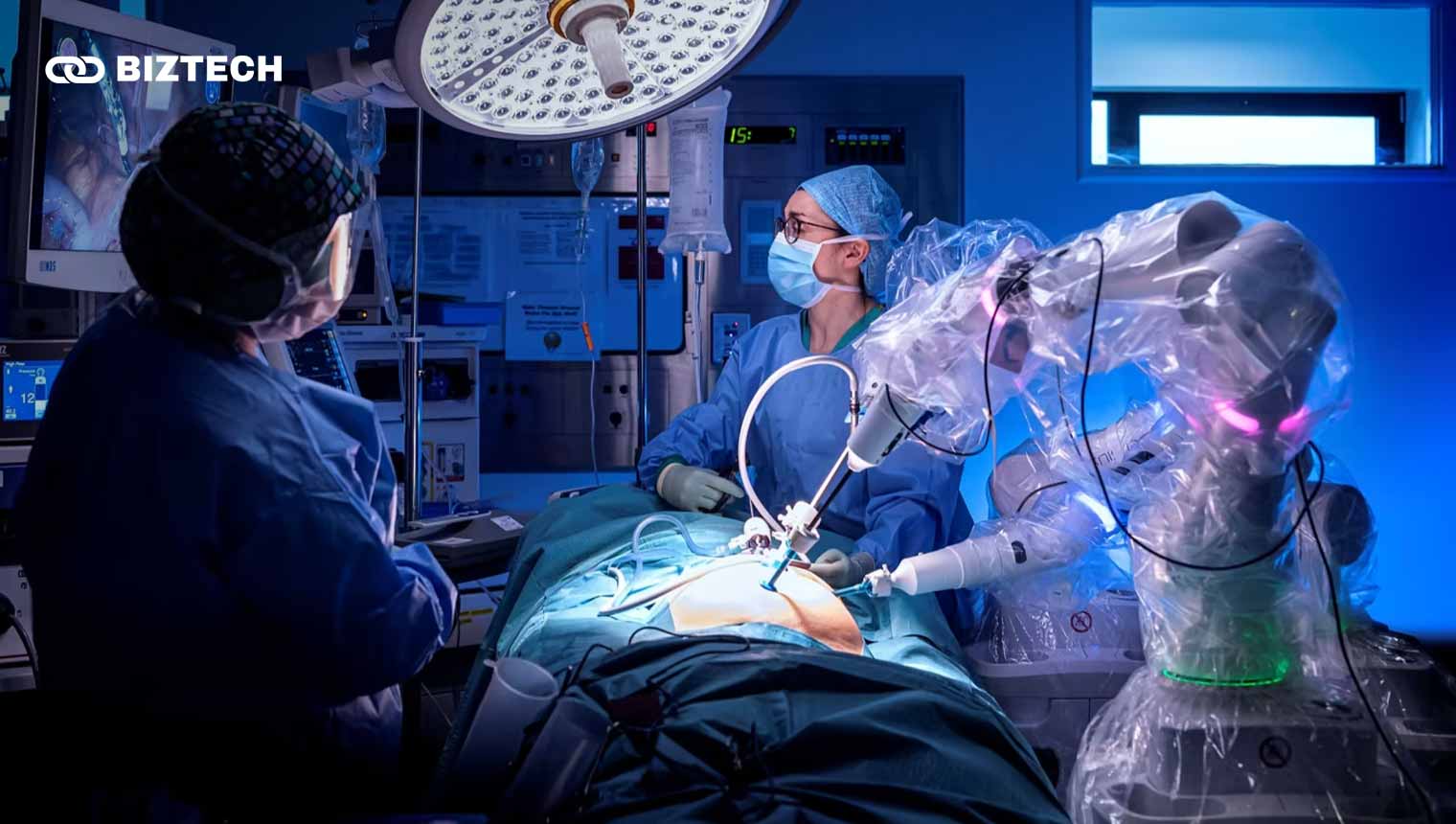

In healthcare, robotic arms give doctors a helping hand during surgery, letting them perform delicate procedures with amazing accuracy. They also support patient care by lifting and moving individuals safely.

Warehouses and logistics companies use robotic arms to quickly and efficiently sort, pack, and move goods. They keep supply chains running smoothly, even during high demand.

Artificial intelligence is making robotic arms smarter. It allows them to learn new tasks and adapt to changing situations. Improved sensors and vision systems make them more precise and reliable than ever.

Challenges Facing Robotic Arm Adoption

Despite their benefits, robotic arms can be expensive to buy and maintain. Smaller businesses often struggle to afford this technology.

Setting up and programming robotic arms can be complex, requiring skilled technicians. This limits their use in industries with fewer resources or expertise.

Some tasks still require human flexibility and decision-making, which robotic arms can’t fully replicate. Adapting them to new or unpredictable environments remains a challenge.

Key Innovations in Robotic Arm Technology for 2025

The future of robotic arm technology holds limitless possibilities. Innovations will make these machines smarter, faster, and more versatile by 2025.

AI and Machine Learning Integration

AI will help robotic arms make better decisions on their own. They’ll learn from experience, adapt to new tasks, and work more efficiently without constant human input.

Advanced Materials and Lightweight Designs

New materials will make robotic arms lighter, stronger, and more efficient. These advancements will make robotic arms better at handling challenging conditions.

Human-Robot Collaboration (Cobots)

Collaborative robots, or cobots, will work safely alongside humans. They’ll have sensors to avoid accidents and help people with tasks that require strength and precision.

Enhanced Precision and Sensory Capabilities

Better sensors and vision systems will let robotic arms “see” and “feel” with incredible accuracy. Haptic feedback will allow them to handle delicate objects without damage.

5G and IoT Connectivity

With 5G and IoT, robotic arms communicate and operate in real-time. With faster responses and the ability to control them from anywhere, these machines will become even more powerful and useful. These innovations will revolutionize industries, making robotic arms more useful and affordable.

The Future Impact of Robotic Arm Technology

Robotic arm technology will shape the future in ways that go beyond just efficiency. It will change how we work, live, and care for our planet.

Economic and Workforce Implications

While robotic arms may replace some manual jobs, they’ll also create new roles in programming, maintenance, and design. Industries will grow, offering more opportunities for skilled workers.

Sustainability and Environmental Benefits

Fewer mistakes mean less waste, and that’s exactly what robotic arms can deliver. They’ll also use energy more efficiently, contributing to greener manufacturing and logistics processes.

Ethical Considerations and Safety Standards

As robotic arms become more common, safety will be a top priority. Strong safety protocols and ethical guidelines will ensure they work alongside humans without risks. These changes will make the future smarter, cleaner, and safer for everyone.

Read also: Types of Robotic Arm: Expert Insights for 2025

Conclusion

Robotic arm technology is moving incredibly fast, and 2025 will bring some really exciting new developments. Smarter AI, better precision, and wider industry applications are set to redefine automation.

Staying informed is key to staying ahead. Whether you’re an engineer, a business owner, or a student, staying informed about these trends can give you a significant advantage.

Be a part of the innovation – don’t just be a spectator. Explore how robotic arm technology can impact your field and take steps to integrate these advancements today!